- #Best Finite Element Analysis Software Software For Structural#

- #Best Finite Element Analysis Software Patch Antenna HFSS#

Best Finite Element Analysis Software Software For Structural

This course shows that this is not necessarily true FE theory can be understood in a few hours and is simple enough to put on an Excel spreadsheet. Global Finite Element (FEA) Software Market: Competitive Landscape. The market analysis includes a chapter solely dedicated for key players operating in the Global Finite Element (FEA) Software Market wherein the analysis provide an insight of the business overview, financial statements, product overview, and the strategic initiatives adopted by the market players.Ansys Mechanical is your solution for finite element analysis (FEA) software for structural engineering. Process induced spring-in manifests with a gap in.Design of electromechanical equipment, such as motors and solenoids requires electromagnetic simulation software specifically designed for magnetic analysis which inherently includes coils and windings and the ability to do transient analysis.

Best Finite Element Analysis Software Patch Antenna HFSS

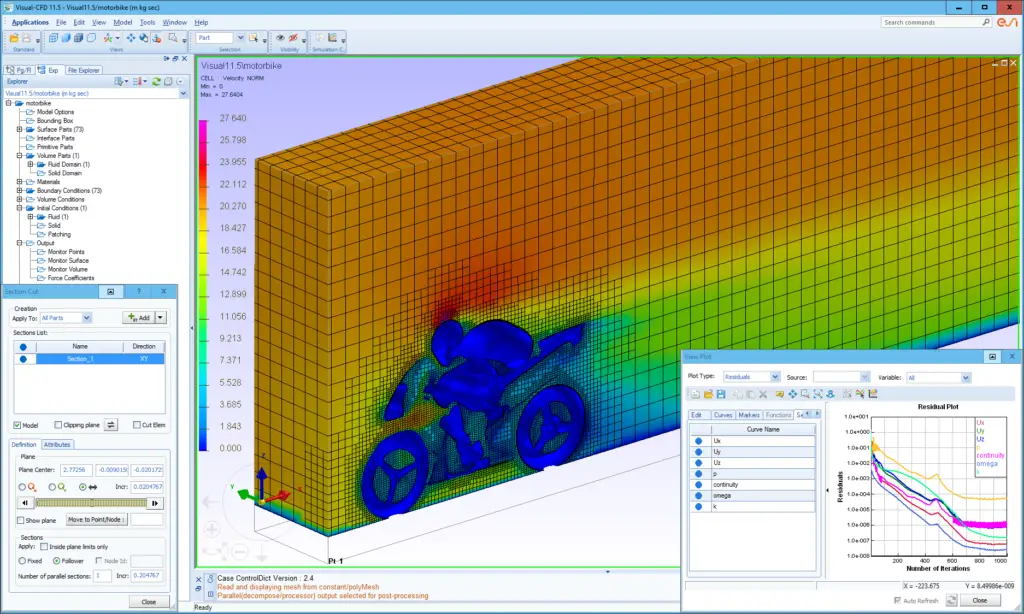

One of the most important engineering analysis techniques. In this article, Jeff Zhang elaborates on his previous work: Computer Aided Engineering (CAE).The following piece highlights the Finite element method (FEM). Micro-strip Patch Antenna HFSS is commercial finite element method solver. But, I personally think it would be better for one to go through the HFSS.Thanks to the parallelization of our programs (included in our packages at no extra cost) the solution speed is certainly a major benefit for the users of CAE software. Let’s take a look at how to quickly perform a finite-element analysis of an Onshape Part Studio in three simple steps (well, actually four).INTEGRATED’s CAE software offers the Finite Element Method (FEM) and Boundary Element Method (BEM) to specifically cater to this wide variety of applications in the magnetic analysis field.Just better. DIANA FEA, General purpose finite element package utilised by civil.

Practical engineering problems have also made indelible contributions to the development of science and technology and engineering applications. In order to meet market demand and be adapted to the rapid development of computer hardware and software technology, functions, performance, user interface, and pre- and post-processing capabilities FEM software products have been greatly improved and expanded.This makes the well-known CAE software on the market meet the current needs of users in terms of function, performance, ease of use, reliability and adaptability to the operating environment, thereby helping users solve thousands of problems. How it beganAs a product of the computer age, FEM is a numerical calculation method developed since the 1960s.The international community began to invest a lot of manpower and resources in the development of finite element analysis programs as early as the early 1960s, although the real CAE software was born in the early 1970s, and the past 15 years have been the development stage of CAE software commercialization. Since the number of elements is limited, the number of nodes is also limited, it is called the Finite Element Method. It is widely used in elastoplastic mechanics, fracture mechanics, fluid mechanics, heat conduction and other fields.The basic idea of FEM is to discretize the structure and use a finite number of simple elements to represent complex objects.The elements are connected to each other through a finite number of nodes, and then they are comprehensively solved according to the equilibrium and deformation coordination conditions.

ABAQUS software has a faster convergence speed and is easier to operate and use. It can calculate the four fields of structure, fluid, heat and electromagnetic, and has won the love of thousands of users in the world.ABAQUS is well-known for nonlinearity solving capability, which covers material nonlinearity, geometric nonlinearity and state nonlinearity, etc. It is based on the earliest linear finite element analysis system mainly used in aerospace and merged with PDA’s PATRAN.DYTRAN was organized and developed on the basis of DYNA3D, which specializes in impact and contact applications.Recently, the non-linear analysis software MARC has been merged to become the largest finite element analysis system in the world.ANSYS software is dedicated to the analysis and calculation of coupled fields. MSC-NASTRAN software has quite a popularity in the aerospace field because of its special relationship with NASA.

For example, ADINA software adopts Parasolid core-based solid modelling technology and can be combined with Parasolid-based CAD software (such as Unigraphics, SolidEdge). Which means after the modelling design of components and parts is completed with CAD software, the model can be directly transferred to CAE software for finite element meshing and analysis.If the result of the analysis does not meet the design requirements, a re-design is required and will be analysed until satisfaction, thereby greatly improving the design level and efficiency.In order to meet the requirements of engineers to quickly solve complex engineering problems, many commercial finite element analysis software has developed interfaces with well-known CAD software (such as Pro/ENGINEER, Unigraphics, SolidEdge, SolidWorks, IDEAS, Bentley, AutoCAD, etc.).Some CAE software adopts CAD modelling technology in order to realize seamless integration with CAD software. Seamless integration with CAD softwareNowadays, one of the development trends of finite element analysis software is integration with general CAD software. Because of its powerful functions in nonlinear solving, fluid-structure coupling analysis, etc., it has quickly become a rising star in finite element analysis software and has become the preferred software for nonlinear analysis and calculation.Finite Element Method The development trend of a finite elementWith the continuous expansion of the application of finite element technology, its development presents the following characteristics 1. And it has both implicit and explicit time integration algorithms.

Automatic hexahedral meshing refers to the three-dimensional solid model program that can automatically divide hexahedral mesh elements.Now, most software can use mapping, dragging, sweeping and other functions to generate hexahedral elements, but these functions can only be used for simple models. the post-processing of the calculation results.Since the quality of the mesh by which the structure discretized directly affects the solution time and the correctness of the solution results, software developers have increased their investment in mesh processing, in recent years, so that the quality and efficiency of mesh generation are both greatly improved, but some aspects have not been improved yet, such as automatic hexahedral meshing of the 3D solid model and adaptive meshing of the model according to the solution results.Most analysis software still does not have this feature. The discretization of the analysis object More powerful mesh pre-processing capabilitiesThe basic process of the finite element method mainly includes three parts:

Therefore, automatic remeshing must be performed. For many practical engineering problems, during the whole solution process, some areas of the model will produce a lot of strain, causing element distortion, which leads to the failure of the solution or incorrect solution results. The emergence of the mesh functionAdaptive meshing refers to a cyclic process of estimating calculation errors, remeshing and recalculating based on the existing meshes based on the results of finite element calculations. Therefore, industries urgently hope that automatic hexahedral meshes replacing tetrahedral elements.

FEM software used to solve structural linear problems have been relatively mature, and the development direction is the solution of structural nonlinearity, fluid dynamics and coupled field problems. Theoretically, it has been proved that as long as the unit used for the discrete solution object is small enough, the obtained solution can be close enough to the exact value. The practice has proved that this is a very effective numerical analysis method. From the solution of the single structure field to the coupled field problemFEM was first applied in the aerospace field, mainly used to solve linear structural problems. For this reason, some companies have spent a lot of manpower and material resources to develop nonlinear solution analysis software, such as ADINA, ABAQUS, etc.Their common feature is an efficient nonlinear solver, a rich and practical nonlinear material library, and ADINA also has both implicit and explicit time integration methods. It is also difficult to learn.

This is the so-called “fluid-structure coupling” problem.As the application of finite element becomes more and more in-depth and people’s concerns become more and more complex, the solution of coupled fields must become the development direction of CAE software. This requires the cross-iterative solution of the finite element analysis results of the structure field and the flow field. When the fluid flows in the elbow, the fluid pressure will deform the elbow, and the deformation of the tube, in turn, affects the flow of the fluid.

0 kommentar(er)

0 kommentar(er)